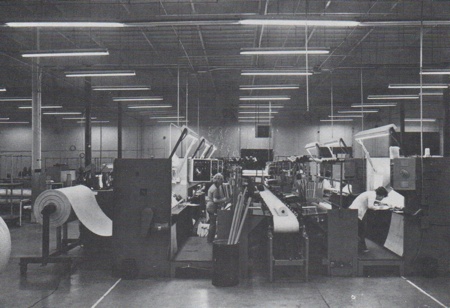

Complete Turn-key Conveyorized Inspection

"Money Saver" - One man can handle the production of 8 to 16 inspection machines

Conveyor Section

Heavy duty 2x4 rectangular steel framework constructed in 10 foot sections for easy assembly.

3 HP gear motor drive with brake system for 90 foot per minute lineal travel and instant stop.

Two 8" diameter main drive rolls with spring load slides to keep tension on converyor belt.

Idlers mounted "V" assembly from semi-circle contour of conveyor belt help prevent fabric from rolling out and eliminate snagging of the fabric.

Automatic Transfer Section

Directs fabric to storage area and then on to weighing station accurately directing one roll at a time.

Weighing Station

Will adapt to your scale and automatically weigh the roll of fabric. A photo-electric system will allow one roll at a time to enter this section. The fabric at this point will either be directed for re-inspection or proceeds to the wrapping station.

Semi-Automatic Wrapper - Model 808

Easy to operate, allows a roll of fabric to automatically advance to a pallet which will move perpendicular to the wrapping area and allow an operator to place the plastic bag around the fabric. THe pallet will then return to its original position and drop the finished roll on a table - ready for shipment.